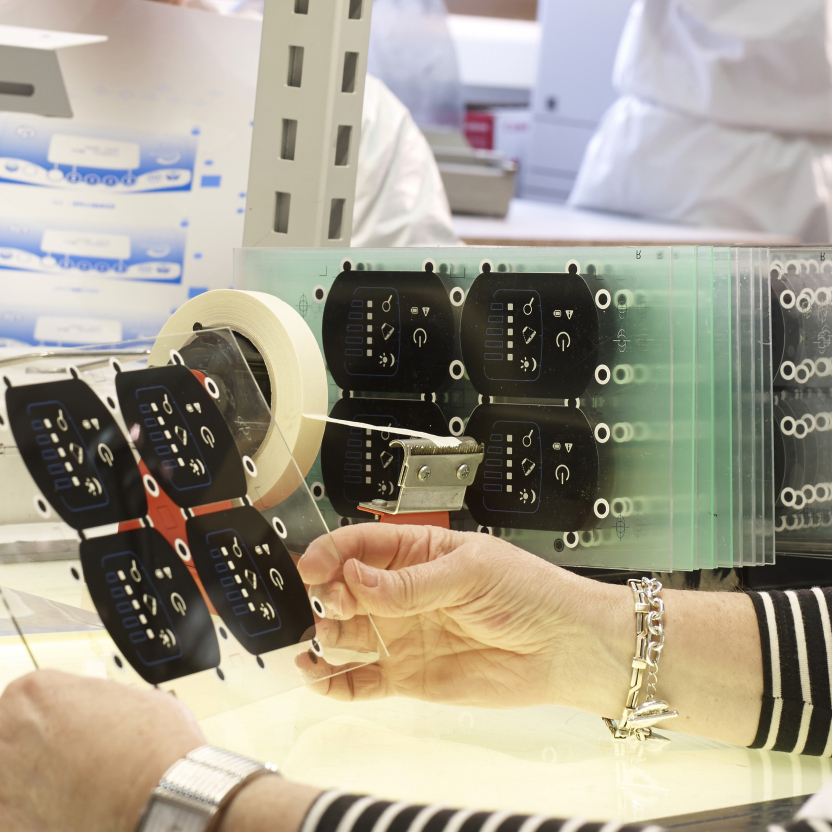

VERTICAL INTEGRATION FOR CUSTOMER SERVICE

One of our major assets is a production mode integrating all design and manufacturing stages, along with the fabrication of specific tooling. This strategic choice allows the company to have a strong quality control over all processes throughout the development of the custom solution and it gives us a close understanding of the technology and its advantages and challenges.